Substrate and compost production

An essential component in your cultivation

The substrate provides support and the proper nutrients for the growth and reproduction of mushrooms. Each mushroom species has specific needs.

There are two main methods to elaborate substrate: Composting with pasteurization and sterilization. Regarding this, we mean pasteurized and sterile substrate.

There are mushrooms that can be cultivated in pasteurized compost or sterile substrate, such as the oyster mushroom (Pleurotus ostreatus), the king oyster mushroom (Pleurotus eryngii) or the Shiitake (Lentinula edodes).

We counsel you in the production of pasteurized compost or either sterile substrate, for the cultivation of several species of mushroom. We can move forward together and find solutions adapted to the specific needs in each facility.

Pasteurized substrates

The pasteurized compost is the most widely used method in the production of substrate for the cultivation of the Button Mushroom and the Oyster mushroom. These substrate types are made from lignocellulosic and protein material such as the straw from cereal and several manure types. The process is made up of 2 differentiated phases:

Phase I Preparation and Fermentation

Wetting of the raw material, mixing and posterior microbial degradation in controlled settings.

Phase II Pasteurization

Compost disinfection to reduce and/or to eliminate competitors.

Both phases are conducted in tunnels, semi-enclosed or enclosed spaces with the following characteristics:

- Aerated pavement

- Forced aeration

- Temperature sensor in both the compost and at the entrance of ventilation

- Oxygen and/or CO2 sensor; only at the pasteurization tunnels

- Computer program to control the process

The result is a homogeneous compost, with the proper characteristics to obtain a uniform and high output in the cultivation phase. Once the compost process is finished, the next step is to inoculate the compost with spawn.

Pasteurized substrate for Pleurotus Ostreatus or the Oyster Mushroom

Phase I – Preparation and fermentation

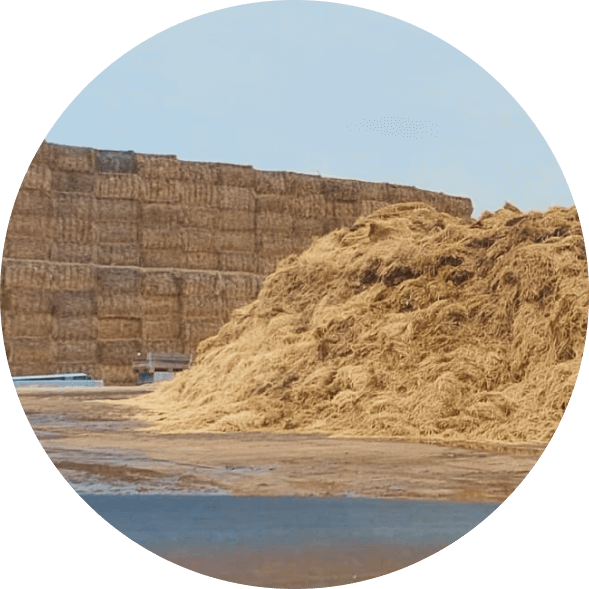

Reception and storage of the raw material: The main raw material in Spain is made up of wheat and corn straw.

Phase I – Preparation and fermentation

Chopping and wetting of the raw material:

The raw material which needs it, is cut to obtain a homogeneous structure. The next step is to wet until the necessary level is reached for the fermentation process.

Phase I – Preparation and fermentation

Mixing of the raw material:

It can be accomplished with the use of a mechanical loader or with more complex mechanical systems.

Phase I – Preparation and fermentation

Fermentation:

This process can be done outdoors or in an enclosed or semi-enclosed tunnel. It is important that this microbe degradation process is aerobic.

Phase II - Pasteurization

Pasterización:

It is done in an enclosed tunnel with the previously mentioned characteristics. During this phase vapor is introduced to achieve a temperature increase in the compost.

The objective is to disinfect the compost to reduce and/or eliminate competitors.

Inoculation

Spawning of the compost:

The compost is inoculated with Oyster Mushroom mycelium, starting the process of colonization of the substrate. A uniform distribution of the spawn is very important

Packaging

The inoculated compost is packaged in 15-20 kg units called compost packages or blocks.

Options after the packaging

· Sale to the mushroom growers: The incubation or Phase III is done by the mushroom growers.

· The company which produces the compost does the incubation or Phase III: When it is completed, the sale and transfer to the mushroom growers facilities is done.

Pasteurized compost for the Agaricus bisporus - Button Mushroom

Phase I – Preparation and fermentation

Reception and analysis of the raw material:

The most utilized raw material in Europe: wheat straw, horse manure, chicken manure, urea, ammonium sulfate and gypsum.

Phase I – Preparation and fermentation

Prewetting:

The wheat straw undergoes a moistening process to guarantee that the proper level of humidity is reached, before mixing it with the rest of the raw material. Pre-moisturizing by immersion is shown in the photo.

Phase I – Preparation and fermentation

Mixture of the raw material:

In the mixing line, the straw packages are broken up and the rest of the ingredients and needed water are added. The result must be a homogeneous compost mass.

Phase I – Preparation and fermentation

Fermentation:

Microbiological or chemical process which is done in tunnels or bunkers. The organic compounds are utilized by the micro-flora. The activity of this micro-flora increases the temperature until a point where there are only chemical reactions. The compost is moved 2 or 3 times to a different bunker.

Phase II - Pasteurization

In this phase, the compost is sterilized with the use of temperature and ammonium, protective micro-flora is developed which aids the extraction of selective substrate for the Button Mushroom and a portion of the ammonia is incorporated as proteins.

Spawning

The pasteurized compost is inoculated with Button mushroom spawn. It is important to make an even distribution of the mycelium.

Options after inoculation

Packaging and sale:

The spawning compost is packaged in 15-20 kg units called compost packages or blocks. These compost blocks are transferred to the grower´s facilities where phase III or spawn run is realized.

Options after inoculation

Bulk spawn run and sale:

The bulk spawn run is done in the interior of tunnels with the same characteristics as the pasteurization tunnels. The compost can be sold in bulk or in trays.

Sterile substrates

The production of sterile substrate is more scalable which means it allows at a small scale and it can grow bigger. Furthermore, with the same facilities, substrate can be elaborated for different types of mushrooms.

Some mushroom species which are grown in sterile substrate include:

- Lentinula edodes – Shiitake

- Pleurotus eryngii – King Oyster Mushroom

- Pleurotus citrinopileatus – Golden Oyster Mushroom

- Pleurotus salmoneus – Pink Oyster Mushroom

- Flammulina velutipes – Enóki

- Pholiota aegerita – Poplar Mushroom

Selection of the raw material

Based on the mushroom species and availability. Agricultural and ranching industry products are often used which are available and can be stored.

Mixing

The chosen raw material is mixed with the help of a mixer in order to obtain a homogeneous substrate.

Substrate packaging

The substrate is inserted into filtered bags, the most appropriate size of the bag and the filter type are chosen.

Sterilization

The filtered bags that contain the substrate are placed in the baskets of the autoclave and are sterilized. The result is a substrate free of competitors.

Substrate cooling

In clean rooms with filtered air.

Substrate inoculation

In a clean room with the specific spawn of the wanted mushroom species.

Substrate incubation

The bags with the inoculated substrate is taken to incubation rooms where the necessary environmental conditions are provided for proper development of the mycelium.

Cultivation

The incubated substrate is moved to growing rooms where the proper conditions for the development of the mushrooms are provided.