Bags and filters

Types of bags

High quality bags with filters are offered at a low cost, which are designed to fulfill the needs in the different sectors, such as mushroom growing, organism production for bio-control, the food industry, the medicinal industry or biomedical research.

We feature two main types of polypropylene (PP) bags:

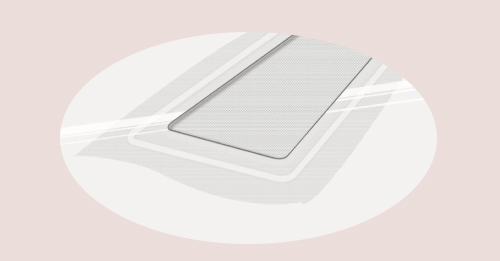

Gusseted bags with side pleats

Gusseted bags are suitable for the elaboration of spawn and substrate.

These bags remain vertically, upright after being filled.

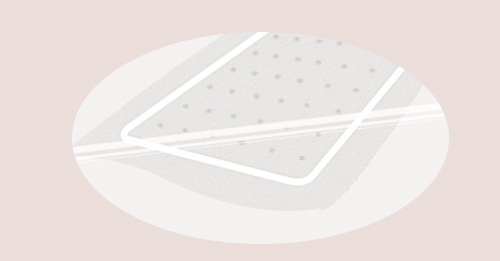

Pillow type bags

Pillow bags are suitable for the elaboration of spawn and substrate utilized in the biological control of pests (bio-control).

The bags are placed horizontally after being filled. High gas exchange.

Features and benefits of the bags

Our mushroom cultivation bags provide the starting point for exceptional mushroom cultivation.

Durability

Our bags won’t break under pressure, sterilization, or movement.

Breathability

Outfitted with innovative filter technology, our bags provide the ideal environment for fungi growth.

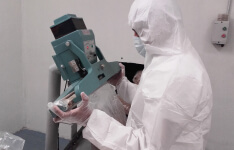

Quality Control

We follow stringent manufacturing procedures to produce dependable, consistent mushroom grow bags.

Safety

Our plastic is U.S. FDA-approved for agricultural use.

Protection

Unicorn Bags uses a resin blend with antibacterial qualities.

Versatility

Adapted to the needs of hobbyists, small producers, and large companies.

How to use the bags

The process is simple and consists of the following steps:

Opening

Manual or automatic opening.

Filling

Filling of the bags (50 to 60 % of its capacity).

Sterilization

Autoclave sterilization.

Cooling

Until approximately 24ºC is reached.

Inoculation

Add the spawn to the substrate.

Sealing

Sealing the bag.

Mixing

Shake the bag to mix its contents.

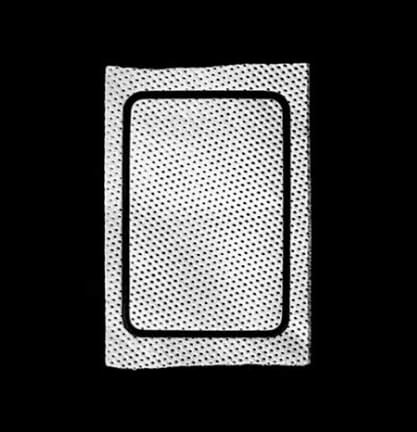

Filters

Essential for efficient farming

Choosing the most appropriate filter depends on factors such as the mushroom species, oxygen needs at the different cultivation stages and the specific conditions of the facilities.

Made with laminates of non wowen polypropylene and Teflon (PTFE), these filters are highly resistant to heat and maintain their integrity during the sterilization which guarantees a consistent pore size.

Filter A

Laminates of non-woven polypropylene and a polypropylene membrane.

Pore size 0.5 microns.

Filter B

Laminates of non-woven polypropylene with PTFE.

Pore size 5 microns.

Filter T

Laminates of non-woven polypropylene with PTFE

.

Pore size 0.2 microns.

Types of perforations

The surface of the bag where the filter is placed needs to be perforated to allow the filter to perform its function. There are two options; one perforation or multiple perforations.

All of the Gusseted bags have only one perforation. The Pillow bags are available in both options, they can be either L holes or Pin holes.

L Hole

Only one perforation whose size is smaller than the size of the filter.

These are used for crops that require high amounts of oxygen during its development.

Pin Hole

Many small perforations.

These are used for crops that require a more stable setting and with less air flow.